Plitek, LLC

For over 50 years, PLITEK® has been an expert contract converter/manufacturer of precision die cut components and converted materials from traditional to the most specialized application. Through our expansive converting capabilities, we manufacture products and components from thin gauge films, plastics, foams, and adhesives. Our unique combination of engineering expertise, materials science, prototyping capabilities, class 8 clean rooms, and vertically integrated manufacturing allow us to provide innovative solutions for even the most complex converting requirements.

Customers turn to us for streamlined manufacturing, material sourcing, and process control.

We work collaboratively with our customers through all stages of their product life cycle from design assistance, material selection, and prototyping to high volume production.

Customizing Precision Converting Solutions for Unique Requirements

Our team understands that each client comes with their own set of specific requirements. Our approach to customization relies on comprehensive and expert-driven approach.

Multidisciplinary Expertise: Our team is comprised of chemists, chemical engineers, mechanical engineers, and electrical engineers, each bringing years of experience across a broad spectrum of materials. This diversity in expertise allows us to understand and address the unique challenges presented by different materials, including engineered resins and adhesive coatings.

Collaboration with Customer Engineering Teams: We believe in a collaborative approach. When faced with a material challenge, we work closely with our customers' engineering teams to provide the most suitable solution. This cooperation is crucial in understanding their specific needs and in developing solutions that are not only effective but also tailored to their unique requirements.

Leveraging Extensive Industry Experience: Our team members, including seasoned chemists, have years of experience in dealing with a wide range of materials. This depth of knowledge is invaluable, especially when dealing with unique materials. Our experience becomes a guiding light in navigating these complexities.

Problem-Solving for Engineered Materials: Engineered resins and adhesive coatings often present unique challenges due to their specific properties and application requirements. Our approach involves a thorough understanding of these materials, their behavior, and how they interact with other components in a product. We use this knowledge to develop effective solutions.

PLITEK® is certified to ISO 9001:2015 and ISO 13485:2016 standards and is FDA, cGMP, and ITAR compliant. We are in the process of implementing and gaining compliance to Health Canada regulations.

CONVERTING CAPABILITIES

- Class 8 Clean Room Manufacturing

- Precision Die Cutting

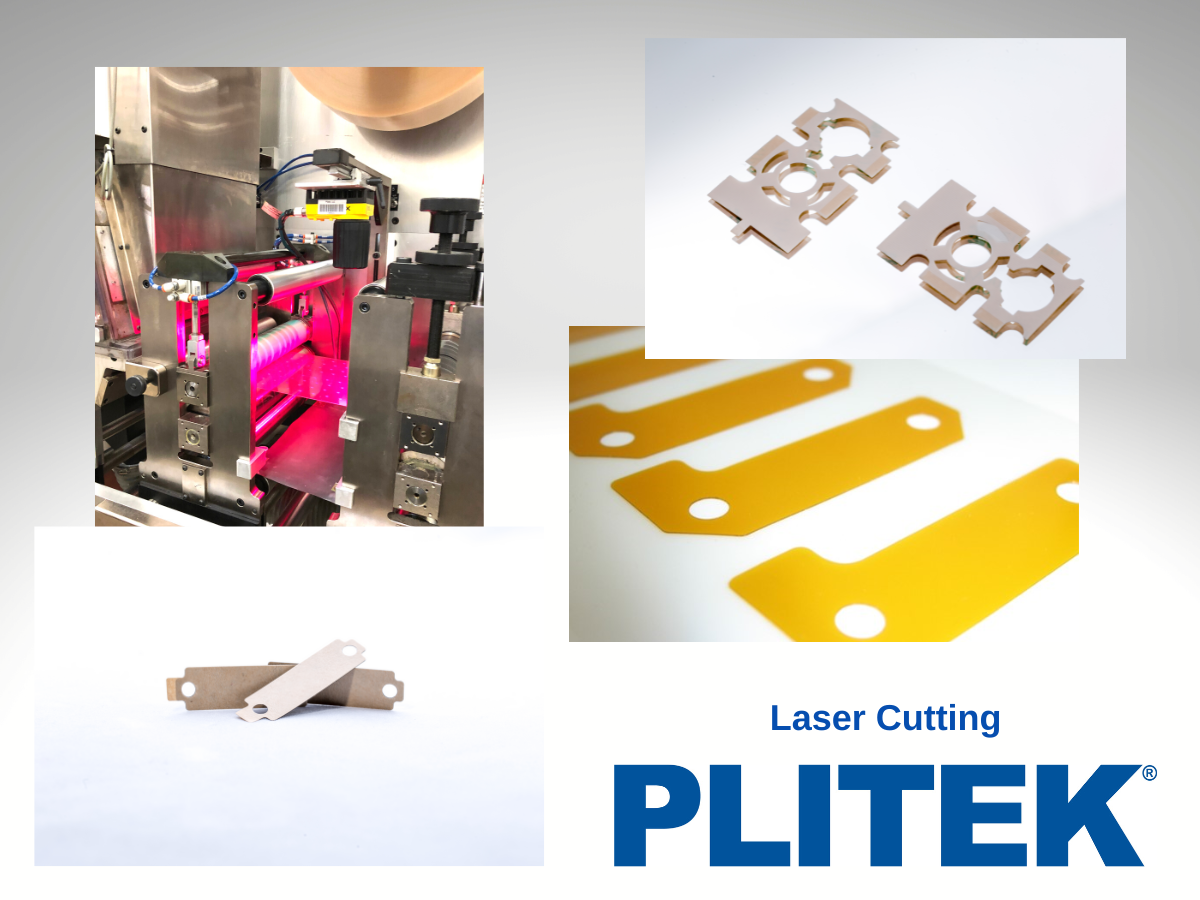

- Laser Cutting

- Custom Room Film Extrusion

- Slitting & Rewinding

- Multi-Layer Laminating

- Adhesive Coating

- Custom Release Liners

- Packaging & Fulfillment Services

For more info contact [email protected]

Our Products

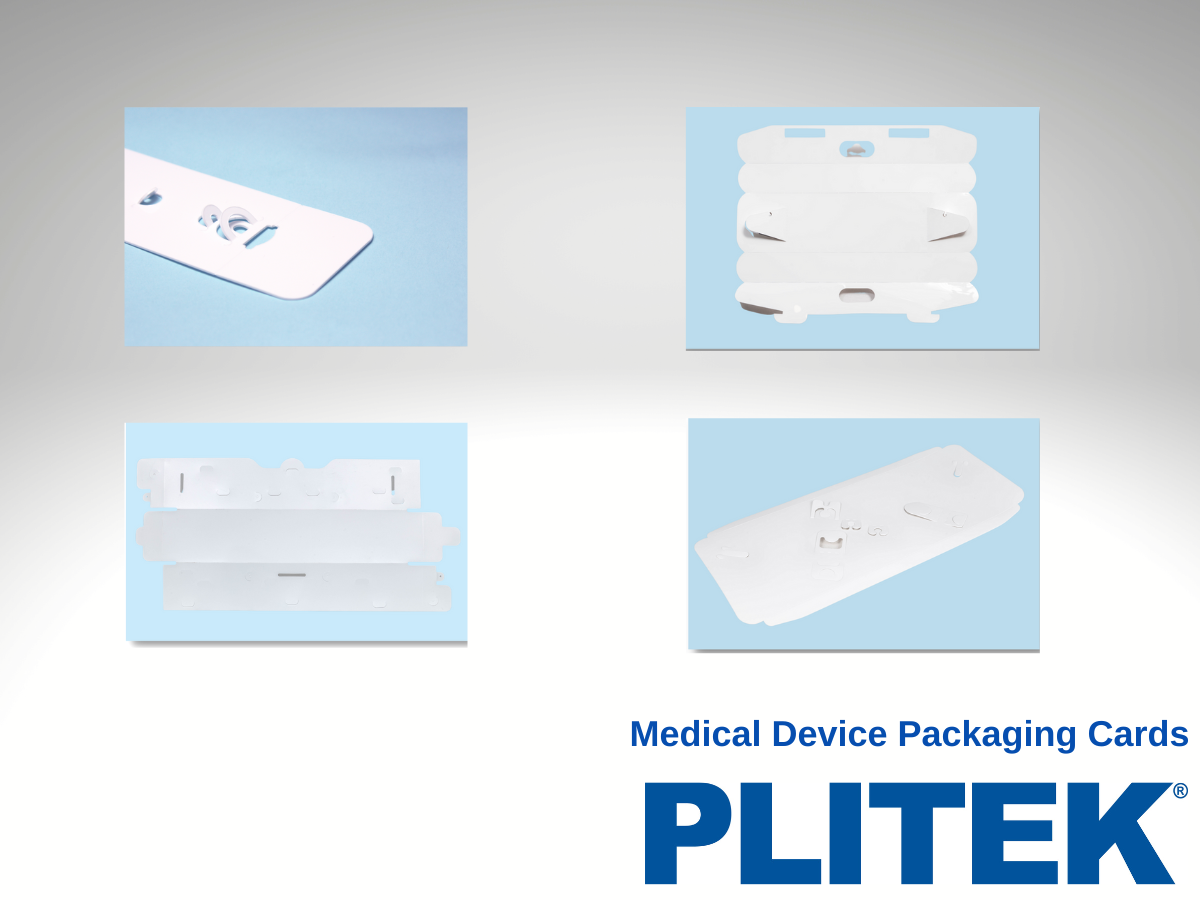

Precision Die Cutting and Converting

Plitek, LLCPLITEK® is a leading manufacturer of custom die cut components and converted materials ...

Clean Room Film Extrusion

Plitek, LLCPLITEK® specializes in extruding custom films to meet specific application requirements. Custom films ca...

Custom Coated Release Liners

Plitek, LLCPLITEK® offers variety of release coated liner chemistries on a range of substrates to suit the mos...

Laser Cutting

Plitek, LLCLaser cutting capabilities enable cutting of complex parts in registration and with tight tolerances. Laser cutting is a thermal...

Adhesive Coating

Plitek, LLCPLITEK® specializes in custom adhesive coating for a range of applications. Our business model has been designed to al...

-file147205.png)