Deep vacuum in record time for advanced analytical instrument applications and turbopumps

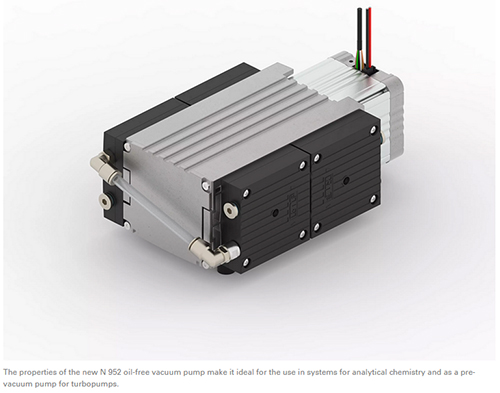

The characteristics of the new N 952 oil-free vacuum pump make it ideal for use in analytical chemistry systems and as a pre-vacuum pump for turbopumps. With this pump series’ ability to generate a deep vacuum quickly and with low vibration, it is suitable for a variety of important applications.

Vacuum as a tool in laboratories and industries

Vacuum is a key tool in laboratories for research and analysis to control chemical reactions. Likewise, vacuum technology plays an important role in environmental technology, analytical technology and hydrogen production, because the requirements for higher throughputs and higher resolution are increasing in these growth markets. The use of turbopumps in industrial applications and research is made possible by a pre-vacuum.

Analysis cell evacuation, pre-vacuum and vacuum profiles for drying ovens

With an ultimate vacuum of up to 1.5 mbar abs. at a flow rate of up to 36 l/min, the new N 952 diaphragm pump series is an important support for many analytical instrument applications. For example, the power of the vacuum pump ensures rapidly evacuated analysis cells. Its speed and retention of high pumping speed even close to ultimate vacuum make the N 952 the ideal pre-vacuum pump for turbomolecular pumps.

Installed in a drying chamber or heating oven, the N 952 diaphragm pump presents two further strengths at once: its speed-controlled vacuum performance for the exact provision of the required vacuum profile and its low-vibration operation.

Constant performance until close to the ultimate vacuum

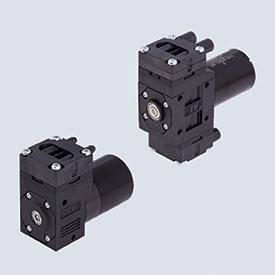

The N 952 has a very good evacuation performance. Depending on the requirements of the process, the four pump heads can be connected in series or parallel as well as other combinations. These head configuration options ensure that the N 952 vacuum pump maintains optimal high and constant performance all the way down to ultimate final vacuum.

Speed-controlled vacuum output, digitally parameterizable for dynamic operating profiles

The dynamics as well as the consistency in vacuum generation are supported by a new generation of in-house developed and produced brushless DC motors. These motors allow the pump to adapt optimally to the performance requirements of the customer's system via speed control. For the end user, this has a positive effect in the form of low vibration and quiet operation.

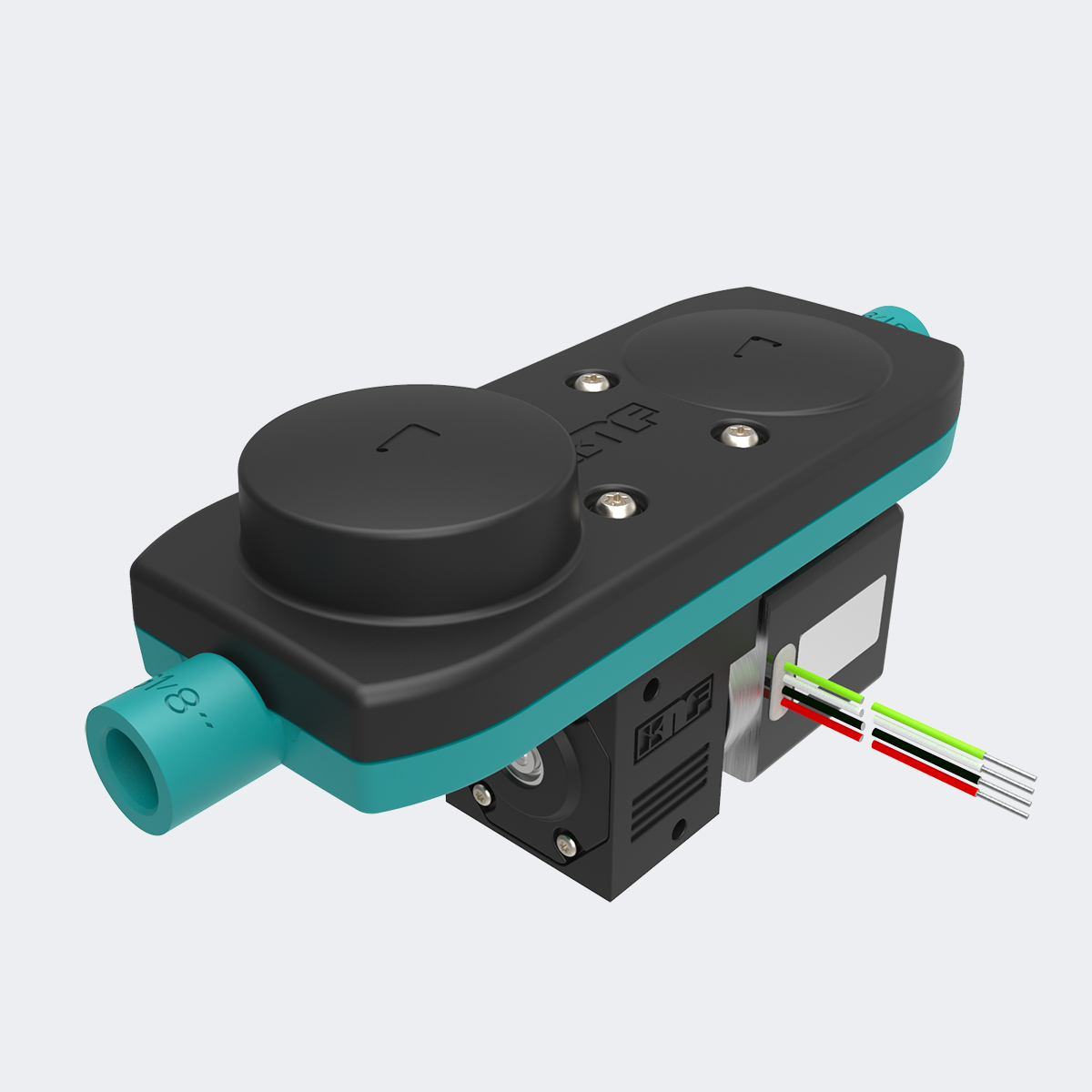

Series model variants for analytical chemistry systems

The chemically resistant vacuum pump with brushless DC motor is available both for 24 V power supply and for AC power supply with automatic mains adjustment for worldwide use. The N 952 meets the requirements of particularly vibration-sensitive applications as a standalone version with a separate power switch. This allows the vacuum pump to be set up separately from the system as a plug-and-play solution.

Typically, the diaphragm pumps of the N 952 series are used for vacuum drying, in combination with turbopumps and in analytical instrument systems. Other areas of application include scanning electron microscopy, mass spectrometry, gas analysis using infrared lasers and gas purity monitoring in hydrogen production from methane. Gas chromatography and systems for NOx detection in exhaust gas analysis further extend the list of systems in which the N 952 is used.

Like all in-house developed KNF motors of the digital customization series, the new generation can be controlled analog, via PWM or digitally. Therefore, the N 952 enables individual operating profiles. With the digital parameterization capability of the brushless DC motor, there are virtually no limits to the definition of specific start-up characteristics, dynamic operating profiles and process-oriented emergency schemes. As a result, the N 952 diaphragm pump precisely delivers the required vacuum and also supports the efficiency targets of the customer’s system.