Aptyx

APTYX: Where Aptitude Meets Excellence to Manufacture Your Competitive Edge.

Aptyx, a new name backed by 70 years of expertise. We’ve brought together the aptitude and excellence of more than a dozen companies with a 70-year plus track record in manufacturing to power smart and impactful manufacturing solutions for our customers so they can solve tough challenges with confidence.At Aptyx, nothing is more important to us than your success. That’s why we’re investing for growth. That’s why we do business with straight talk, speed and a commitment to quality. And that’s why we bring a collaborative approach to complex manufacturing so that you can bring more innovative and life-changing solutions to people who need them.

We help teams bring complex components and devices from idea to market success with entrepreneurial speed and sustainable results. We provide decades of deep expertise and a global network of facilities spanning the US, Mexico, Canada and China for flexible production options. As a single-source provider, we excel at a broad range of specialized capabilities including:

- Engineering

- Tooling design & fabrication

- Molding – injection, dip and blow molding

- Extrusion

- Coatings – application and automation design & build

- Assembly

Let's make something great happen together.

++++++++++++++++++++++++++++++++

OUR GLOBAL STRENGTHS, BY THE NUMBERS

- 70+ years of experience

- 10+ locations worldwide

- 1000+ team members

- 120+ injection molding presses

- 95+ dip molding cells

- 80+ extrusion lines

ENGINEERING

Engineering is the heartbeat of our company. Our entrepreneurial heritage is driven by the expertise and vision of groundbreaking engineers who have the ingenuity to find innovative manufacturing solutions to achieve leading edge performance requirements.

Aptyx offers a full suite of engineering services, including:

- Scientific qualification with RJG Master Molder®-qualified engineers

- IQ/OQ/PQ full capability studies

- Mechanism development

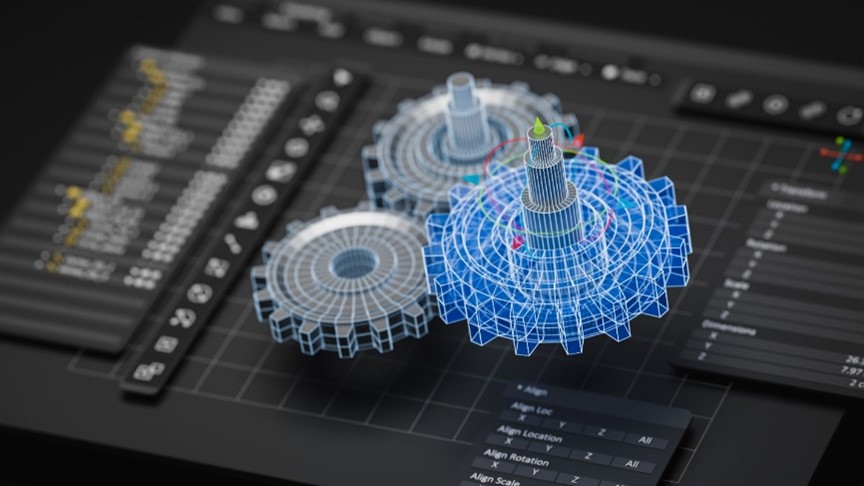

- Complex CAD surface modeling

- Design for manufacturing

- Materials and process technologies

- Design for assembly and cost reduction

- Modular tooling systems

- In-house tool design

- Complete tool build capabilities

COMPLEX INJECTION MOLDING

Our history starts with molding; it’s a core strength. We opened operations in 1949 with the founding of Seitz, a leader in complex injection molding and in particular, precision gears that drive modern applications in robotics, drug delivery and more. We have unmatched depth and breadth of experience in complex processes such as overmolding, two-shot molding, insert molding, and in-mold decorating. We’ve worked with nearly every resin on the spectrum and can help you to choose the best material for your project. We employ scientific molding principles and Kistler sensors, systems, and software solutions for quality assurance. With 120+ injection molding presses ranging from 5 tons to 940 tons, we have the equipment and know-how for any job, large or small.

DIP MOLDING

No one has more dip molding expertise than we do! We were a pioneer in dip molding nearly 60 years ago when Molded Devices was founded and we remain a leader, having acquired many companies along the way to strengthen and support our offering. Dip molding has many advantages over other techniques, including quick prototype development, lower tooling costs, and thin elastic wall features. Our dip molding facilities include both manual dip molding cells for prototypes and low production volumes as well as automated dip molding production lines for high-volume production. With nearly 100 dip molding machines, we are one of the largest, most diverse dip molders in North America. Examples of dip-molded products include medical balloons, cuffs, and nasal and arterial cannulas.

BLOW MOLDING

When you need a hollow plastic part, blow molding is the answer. We have the in-house capabilities, tooling, and knowledge to fabricate your custom blow-molded component and can prototype the parts and molds you need. Whether you need high-volume 4+4 continuous extrusion blow molding or micro medical blow molding for complex components like medical balloons and cuffs, we have the capabilities to bring your product ideas to reality.

EXTRUSION

Fun fact: We make 40 million feet of extruded smoke evacuation tubing every year. That’s more than 7,500 miles—enough to stretch from our headquarters in Tempe, Arizona, to our manufacturing facility in Guangzhou, China! With more than 35 years of plastic extrusion experience and 80+ extrusion lines, we’re a trusted innovation partner for extruded medical tubing, supplying millions of feet of plastic tubing annually to OEM and CMO customers around the world. Our broad product range incorporates a full line of single-lumen and multi-lumen tubing, as well as core mandrels for a range of catheters and other interventional devices. We also are a leader in corrugated and expandable medical tubing and plastic fittings used in surgery, anesthesia, respiratory, CPAP, and other applications.

COATINGS

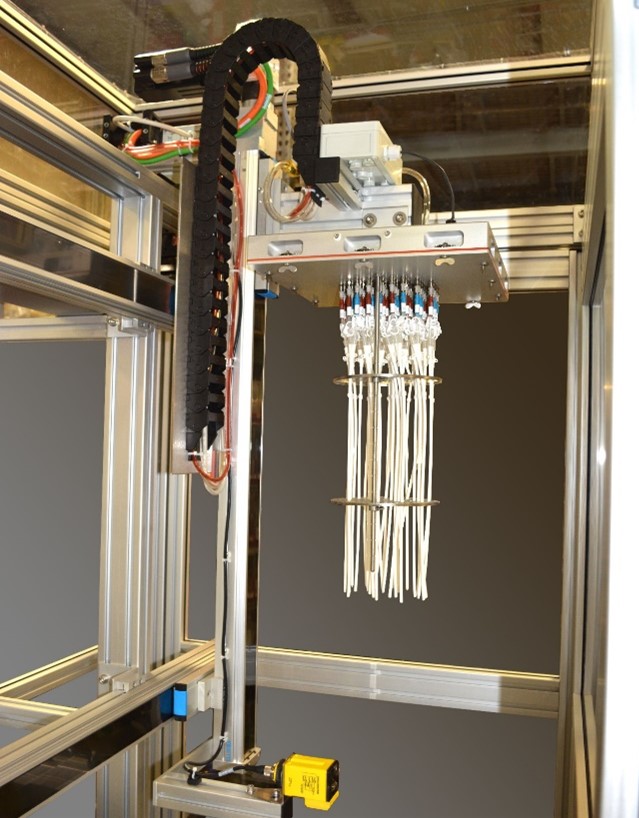

We provide full-service solutions for your coating needs, from helping you to identify the right coating for your product to designing, building, and installing the highly automated equipment to apply it - either in your facilities or ours. With decades of unmatched experience, we’re the leader in automated systems for the application of a wide range of dip and spray coatings for the medical device, pharmaceutical, and other industries. Life science applications include drug-eluting, and biocompatible coatings, as well as lubricious coatings to ensure smooth deployment for drug delivery applications such as autoinjectors. We currently support customers in more than a dozen countries and have completed more than 500 projects in the last two decades.

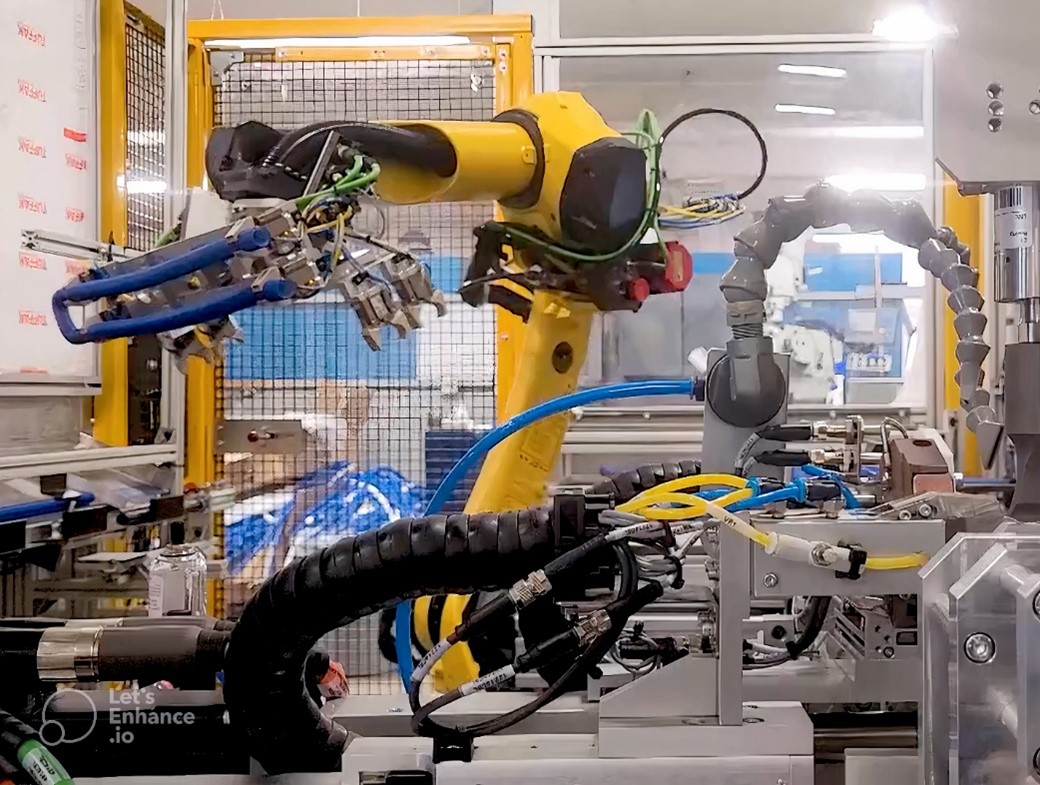

ASSEMBLY

As an ISO 13485 and FDA registered full-service provider, we offer a range of controlled environments for your assembly needs, including ISO 7 and 8 cleanrooms and whiterooms. We provide manual and automated assembly, as well as supporting services including molding, extrusion, packaging, and sterilization management on the back end. We have a long track record of manufacturing and assembling medical devices such as catheters, cannulas, tubing sets, infusion pumps, and single-use and reusable instruments.

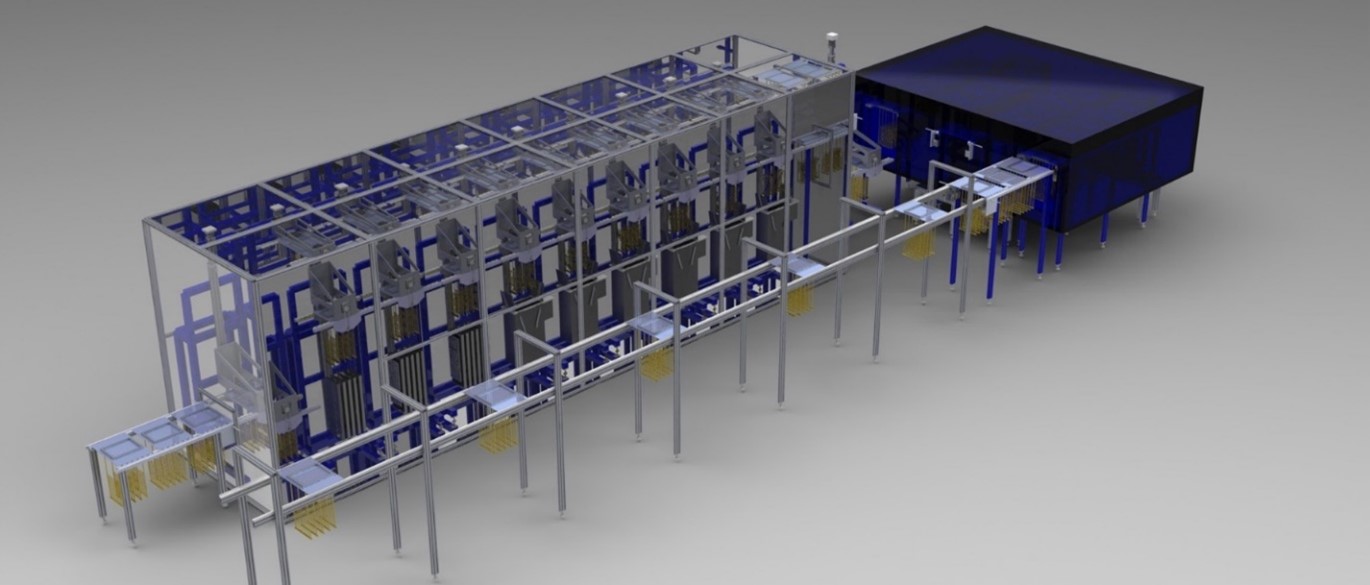

EQUIPMENT & AUTOMATION

With decades of unmatched experience, we’re the partner of choice for highly reliable and innovative dip molding and dip coating equipment. Our advanced technology has revolutionized the industry, including high-volume, fully automated, continuous-motion and robotic batch systems custom designed for your product, process, and volume requirements. Our experienced technical staff offers mechanical and electrical design, installation, supervision, project management, equipment troubleshooting, and maintenance support globally.

DESIGN SUPPORT

With a focus on design for manufacturability, we invest time up front to ensure that your tool will reliably produce optimal manufacturing outcomes. With our experience, expertise and investments in engineering software such as Moldflow®, we can predict, understand and mitigate the negative effects of polymer behavior before a mold is built. Spotting and understanding the root causes behind high shear, sink, weld lines, flow traps, flow hesitations, and warp are essential for producing quality parts. Working in advance with your engineers, we can optimize designs to reduce, eliminate, and even reverse many negative effects, including warp. We are happy to get involved early in your process to help develop designs that will successfully scale into high production.TOOL DESIGN & FABRICATION

Every successful molding and extrusion process begins with a high-quality, precision-manufactured, well-maintained tool or die. Meet our team of experts, including tool makers and RJG Master Molder®-qualified engineers and technicians. We have a full range of tooling services, including in-house custom tooling design, both in-house and partner tool-build capabilities in several geographies, tooling support services, and in-house tooling maintenance. Our capabilities include Q-DRIVE rapid tool manufacturing, modular tooling systems, Decoupled Molding® techniques, Moldflow® simulation and analysis, and the MUD® Quick-Change System to deliver increased uptime and reduce costs.