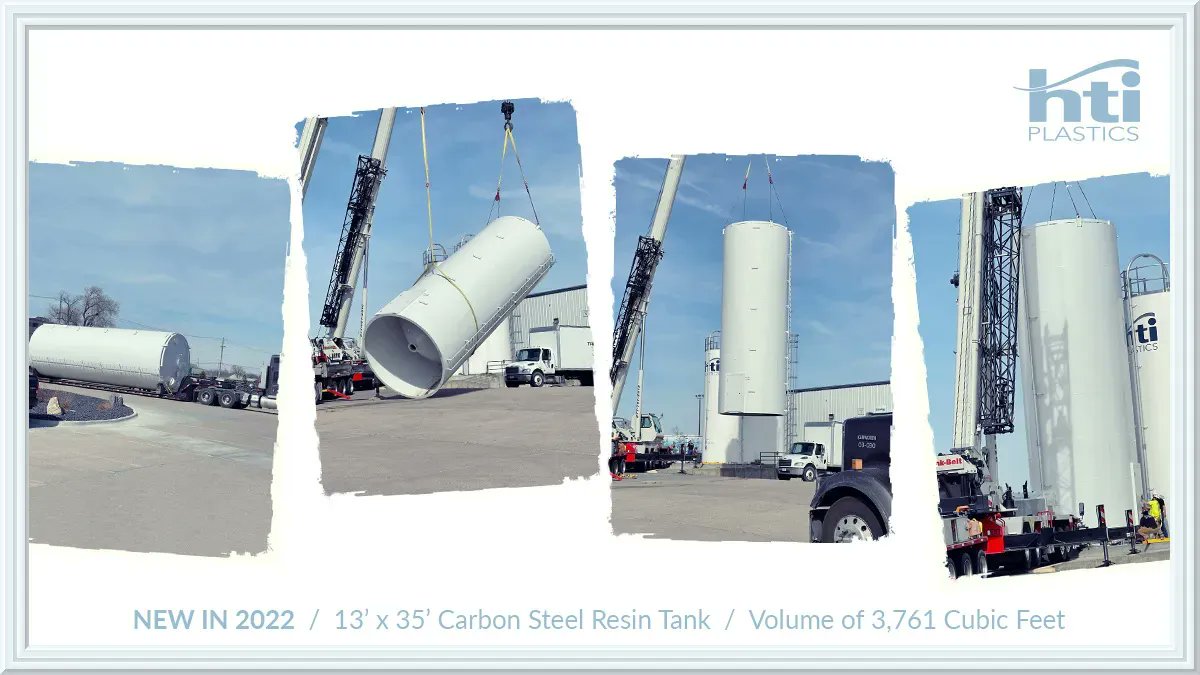

More plastic requires more tanks. HTI Plastics adds a brand-new plastics resin silo to its arsenal of manufacturing equipment.

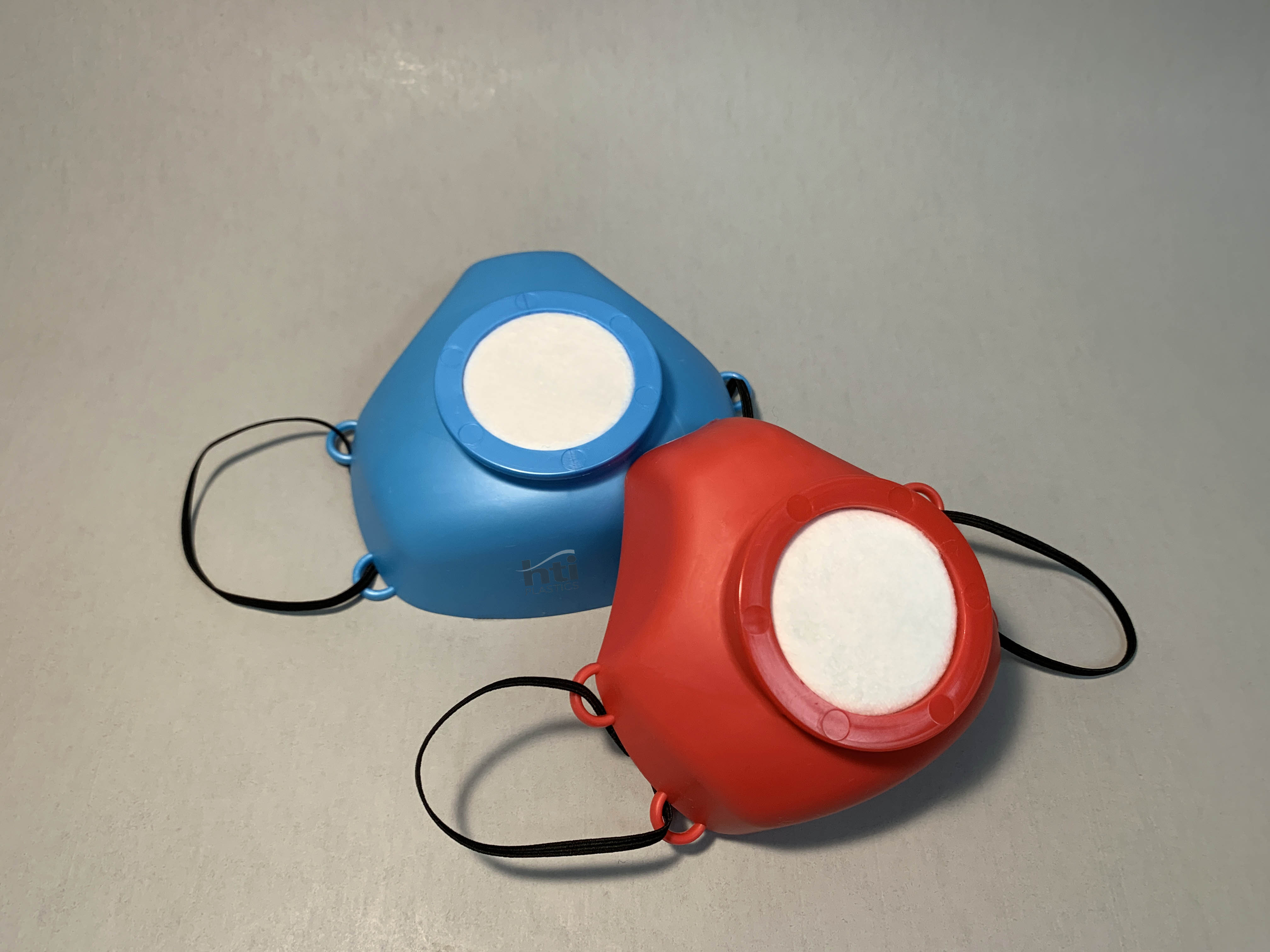

LINCOLN, NE, UNITED STATES, April 14, 2022 /EINPresswire.com/ -- HTI Plastics adds new outdoor storage silo, for added plastic resin capacity. More plastic requires more tanks. With that being said, HTI Plastics adds a brand-new plastics resin silo to its arsenal of manufacturing equipment in 2022.Details consist of a 13' x 35' welded carbon steel resin silo with a volume of 3,761 cubic feet. The new welded carbon steel silo has an estimated capacity of 123,305 lbs. (3,523 cu ft). The HDPE pellets are free flowing with a bulk density of 35 lbs/cuft. The inside of the welded steel silo is a non-corrosive, epoxy coating to protect material from oxidation, keeping your material contamination free. The outside is primed, and enamel coated to prevent rusting. Welded silos are guaranteed to be water-tight. No bolts, seams, or gaskets on these select models of plastic resin silos. Yes, the exterior is great, but how about the smooth welded finish on the interior of the silo, eliminating material hang-up points. We’re excited to add this additional piece of equipment to the HTI Plastics manufacturing plant, knowing this will help add higher volume capabilities to our production process, for the end purpose of exceeding our customers product needs and expectations. Founded in 1985, our humble entrance into the plastics manufacturing business was as a small molder, in-house engineering, and tool room, and we trace our product debut to the design and manufacturing of one of the first vaginal applicators. Today, our plastic pharmaceutical applicators are used in a wide range of treatments in both prescription and over-the-counter markets, and we’ve expanded into the design and production of custom and proprietary thermoplastic injection-molded products for a variety of pharmaceuticals, animal health, food packaging, sporting goods, and other custom products.

35' Resin Silo

View website