Glebar recommends that manufacturers upgrade legacy machines to the newest operating system from Microsoft, Windows 10

Glebar recommends that manufacturers upgrade legacy machines to Windows 10, the newest operating system from Microsoft, for the latest in security protection and to reduce downtime caused by technical issues.

Machines that run on outdated operating systems are more vulnerable to malware, viruses, and other security issues. Since Microsoft no longer supports Windows XP and Windows 7, it can leave manufacturers vulnerable.

“Upgrading legacy machines to Windows 10 will provide the latest security protections, allowing manufacturers to focus on serving their customers without worrying about potential security threats,” explained Mark Scanel, VP and General Manager of Glebar Customer Care.

Finding solutions to technical issues for unsupported operating systems can be time-consuming, increasing downtime. By upgrading to Windows 10, Glebar technicians can work with Microsoft Support to quickly find a solution, reducing downtime.

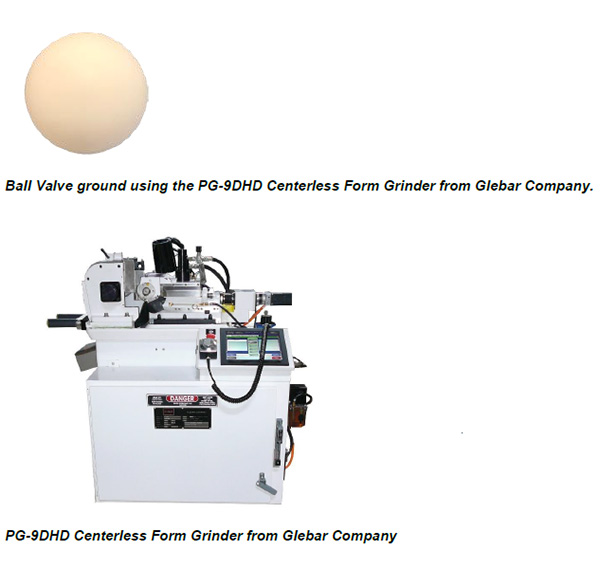

Glebar can upgrade any of their Windows-based machines to Windows 10, including their CAM.2 and GT-9AC Micro Grinding Systems and their P4K Gauging System.

The Glebar Customer Care team works with customers to minimize downtime and maximize the capabilities of their machines to increase production efficiencies and return on investment.

For more information visit the Glebar website, send an email to [email protected], or call (201) 337-1500.

###

About Glebar Company

Glebar Company (www.glebar.com) is an innovative, vertically-integrated, process improvement company that designs and configures its standard platform of modular precision centerless grinding machine systems to provide turnkey, custom solutions for its customers. The company focuses on delivering a process to its customers while maximizing customer return on investment. Founded in 1952, Glebar serves companies all over the world, across many market segments including medical, industrial, aerospace, automotive, consumer goods, and mining. Its machines are known for their precision, longevity, flexibility, and efficiency.

Glebar machines are made to the highest quality and safety standards. Every machine is backed by a 24/7 customer service operation which includes a team of technicians, design engineers, and customer service representatives. The company also stocks a stand-by inventory of critical parts and tooling for next-day delivery in the U.S., Europe, and Asia. It employs a dedicated applications team conducting research and development activities, customer process enhancement, and pushing the limits of grinding wheel technology. Glebar is an ISO 9001:2015 Certified Company and is ITAR Registered.

In 2020, Glebar Company expanded its capability and is now offering Electrochemical Grinding (ECG) technology, through the acquisition of ECG leaders Tridex Technology and Everite. Glebar now offers innovative turnkey ECG manufacturing solutions designed to improve cycle times, maintain quality levels, and allow operators to easily set up and run multiple machines.

For more information about Glebar, call (201) 337-1500, visit www.glebar.com, or send an email to [email protected].

David Manis

Digital Marketing Specialist

Glebar Company

[email protected]

(201) 644-2046