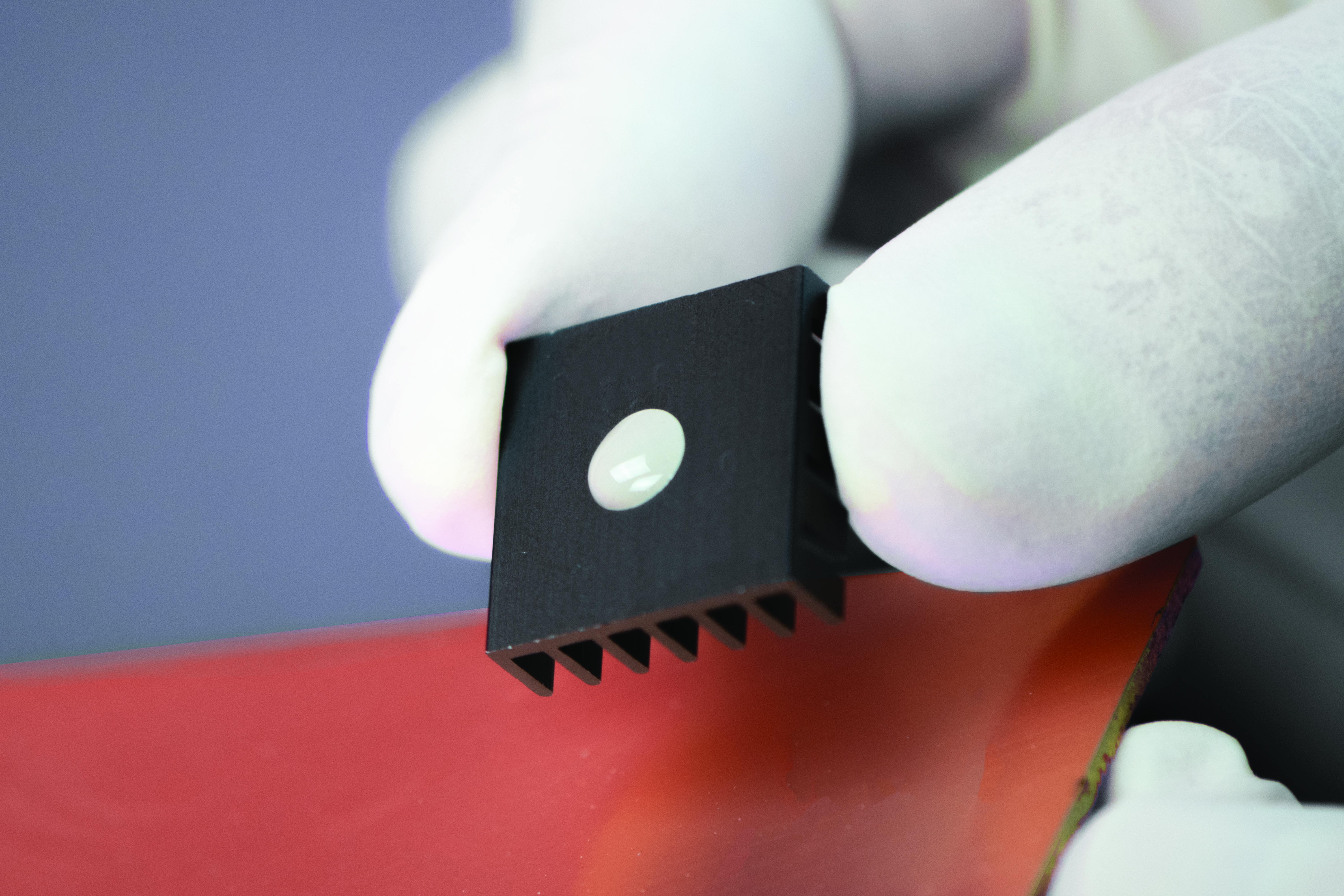

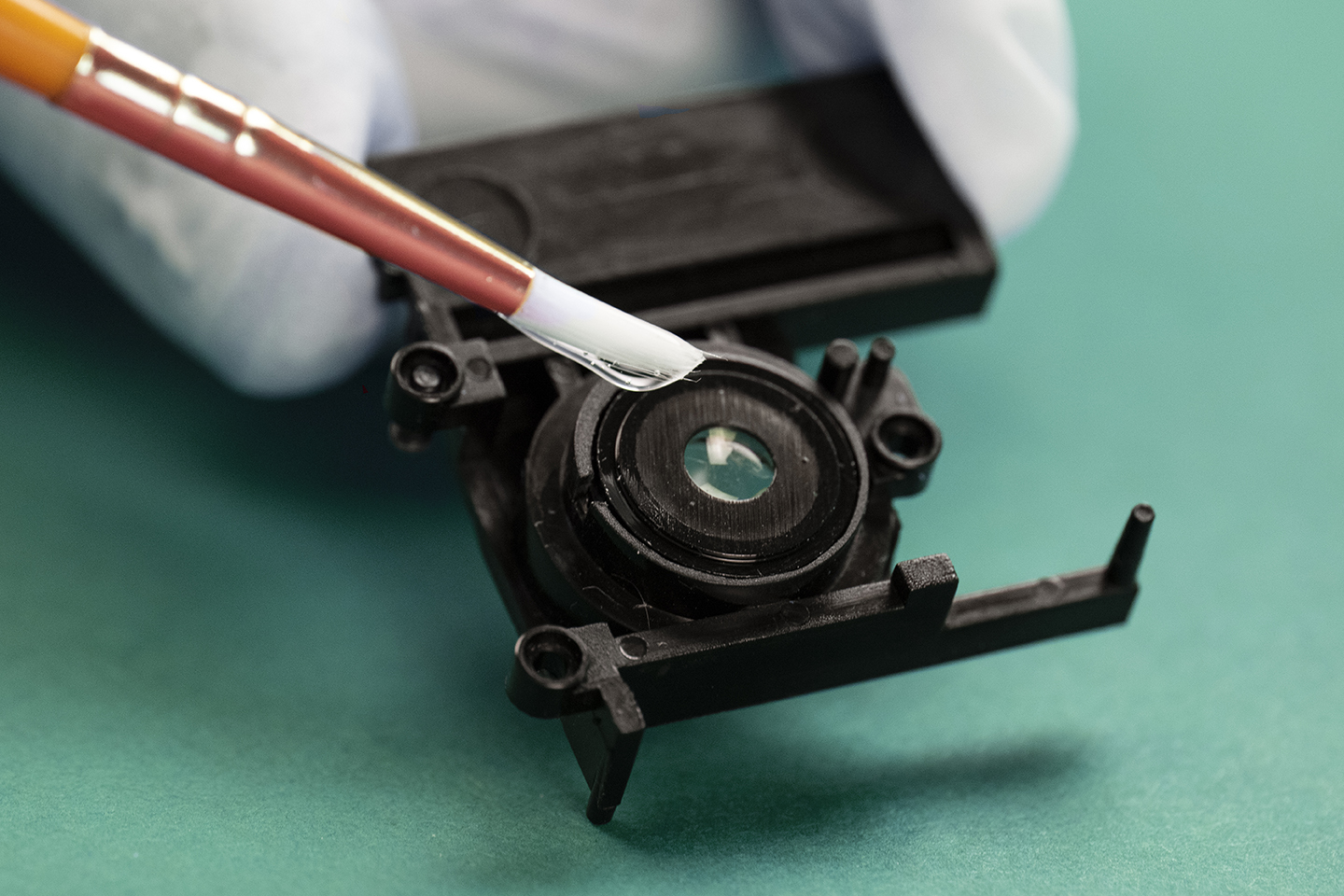

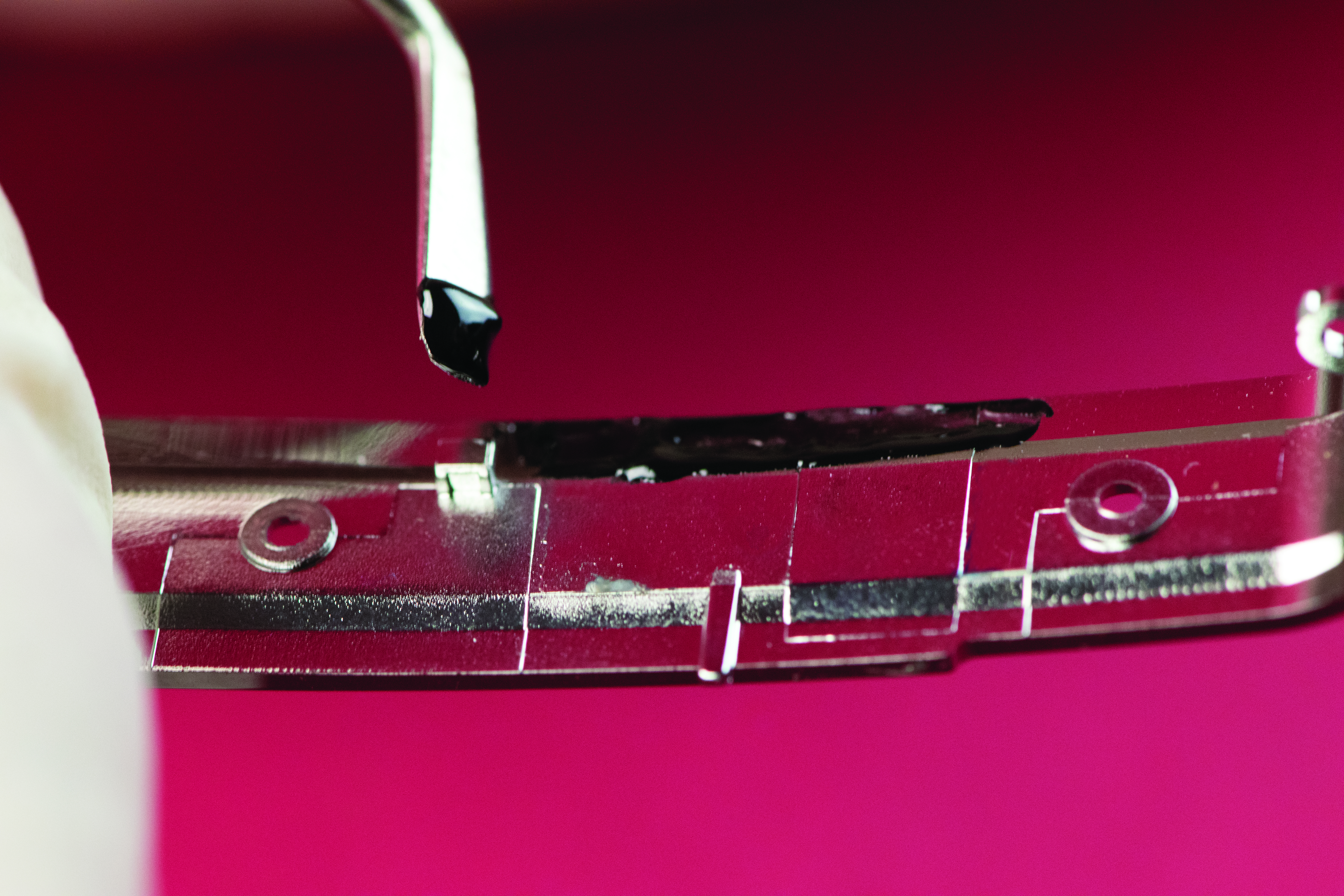

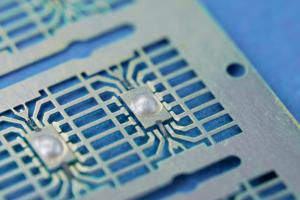

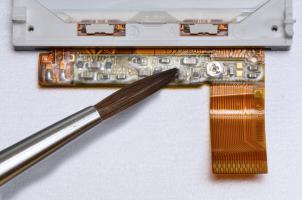

MasterSil 972TC-LO is capable of transferring heat while retaining superior dielectric properties. It bonds well to a wide variety of substrates, including metals, composites, glass, ceramics as well as many types of rubber and plastics. The system has very good flexibility and elongation. It can withstand aggressive thermal cycling as well as thermal and mechanical shock. The system is 100% solid and has a white color.

Master Bond MasterSil 972TC-LO passes the rigorous requirements for low

outgassing per ASTM E595 specifications. It is particularly well suited for use

in vacuum environments as well as applications in the aerospace, electronic,

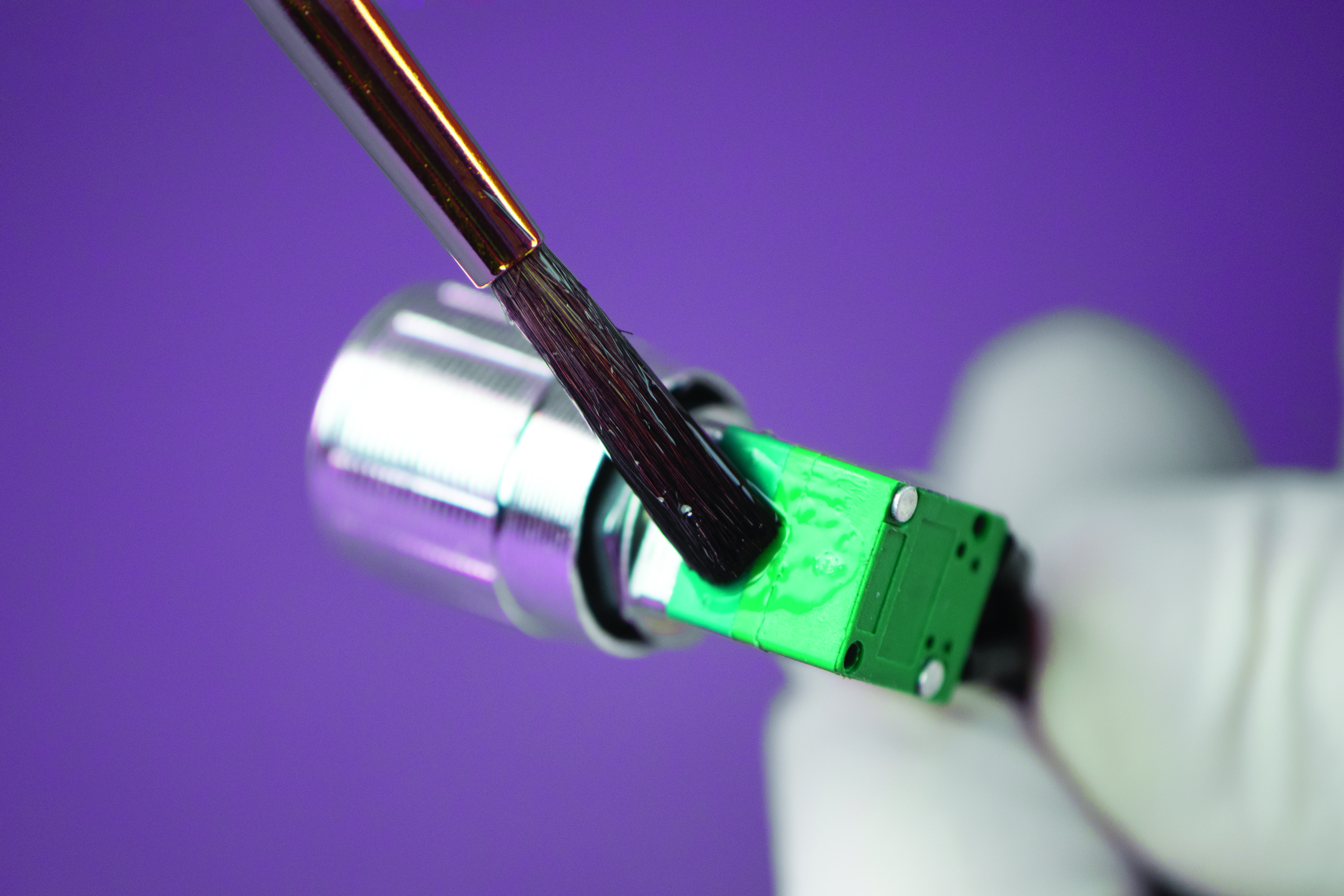

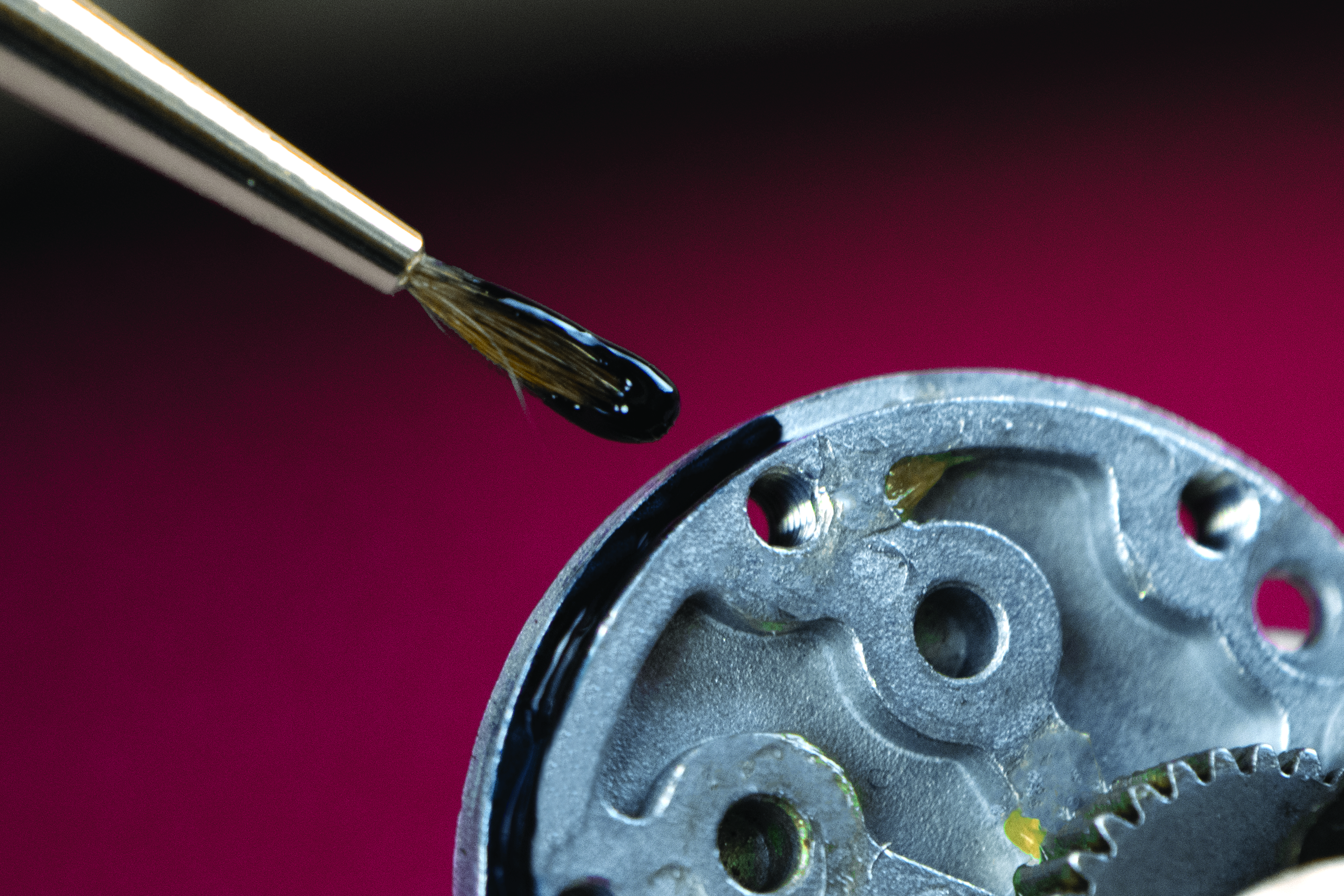

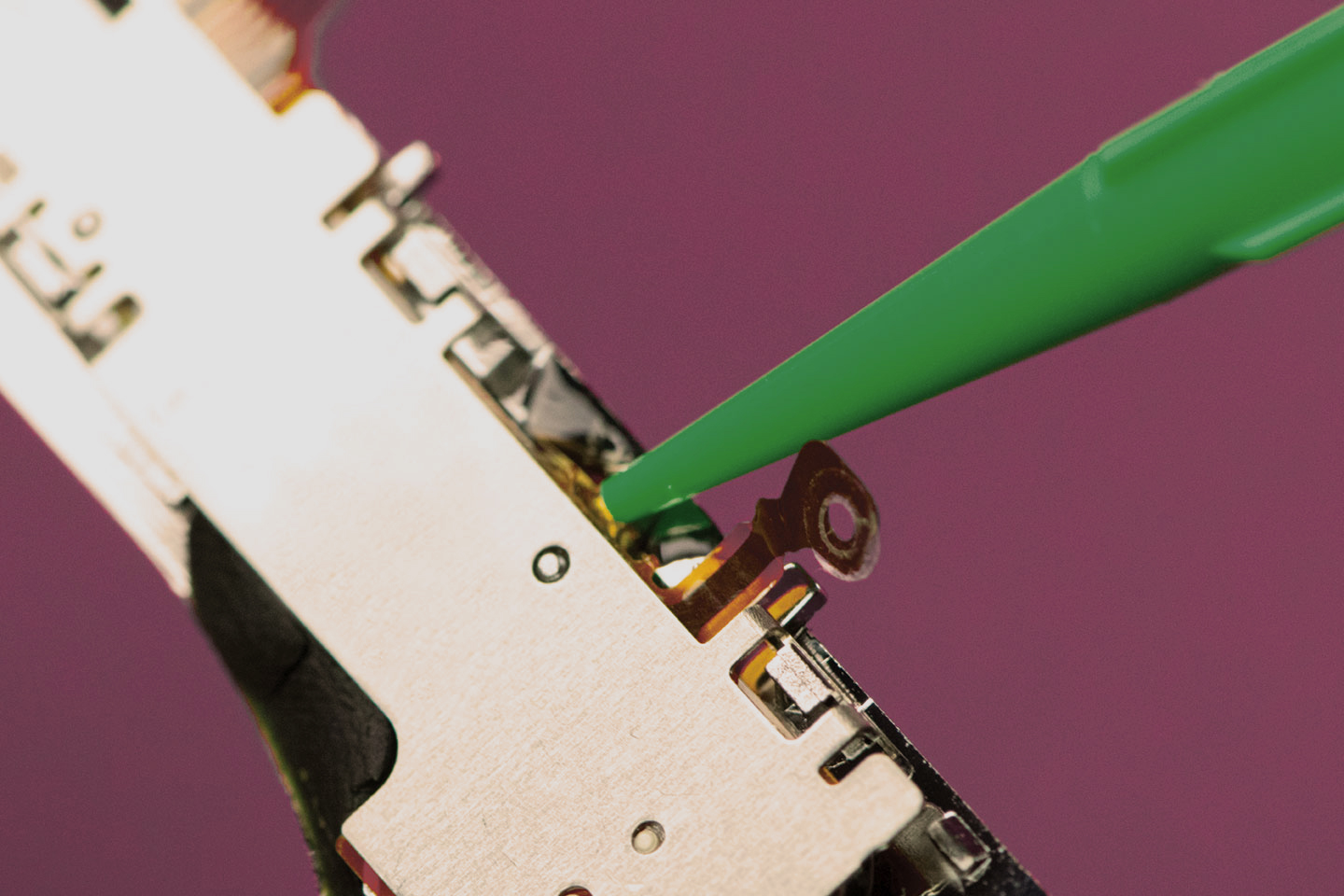

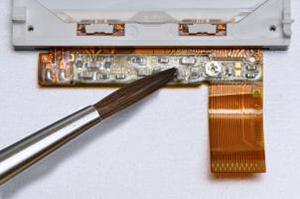

opto-electronic and specialty OEM industries. This two part silicone system

offers convenient handling for bonding, sealing, coating and potting.

MasterSil 972TC-LO is an electrically insulator that has a thermal

conductivity of 7-9 BTU•in/ft²•hr•°F [1.01-1.30 W/(m•K)]. It bonds well to a

wide variety of substrates, including metals, composites, glass, ceramics,

rubbers as well as many types of and plastics. Highly flexible, MasterSil

972TC-LO has an elongation of 40-80%, withstands aggressive thermal cycling and

resists mechanical shock. This heat dissipative silicone system has a wide

service temperature range is -120°F to +400°F.

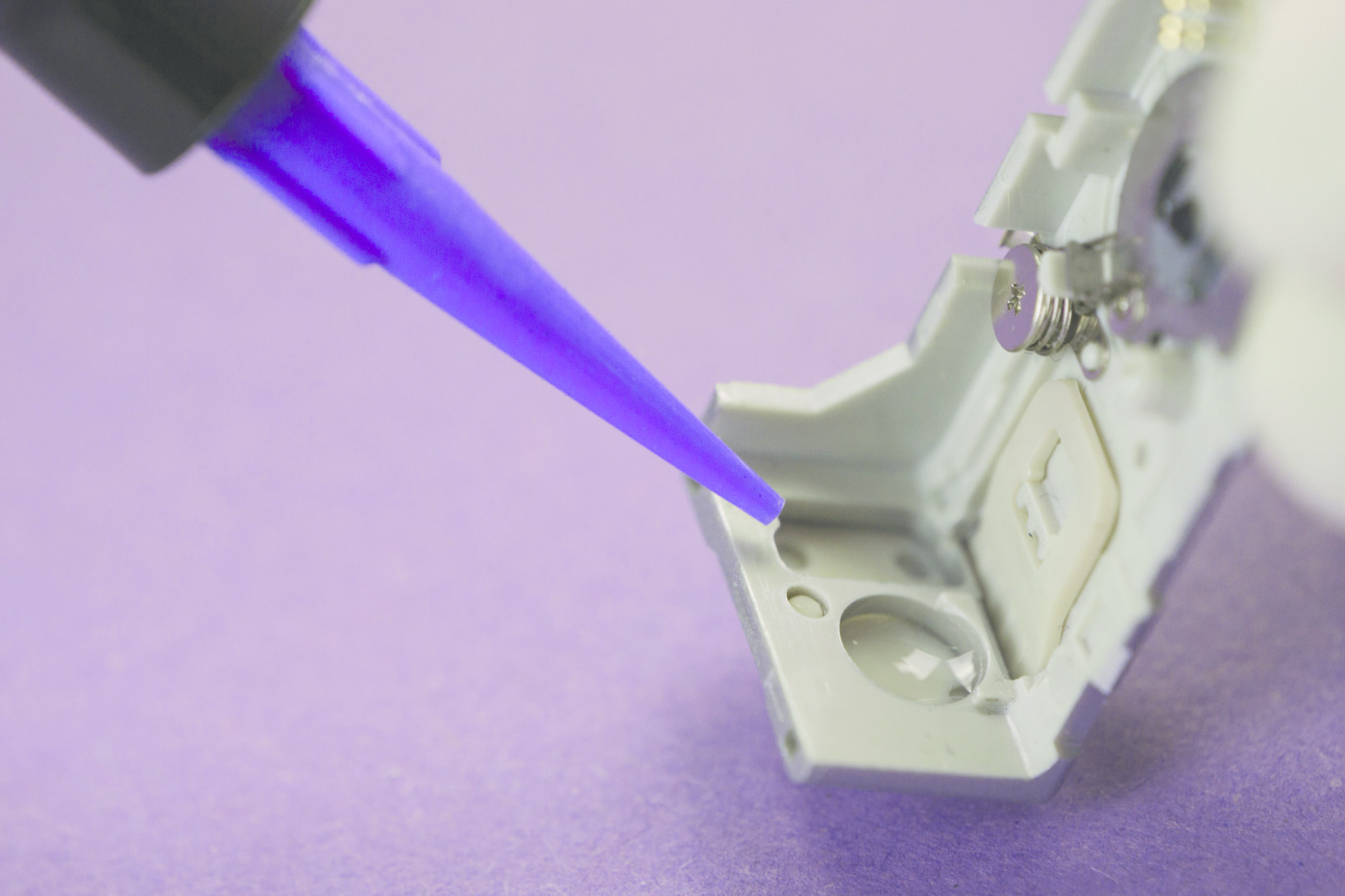

This addition cured system does not require air for cross-linking. It

features low shrinkage upon curing even in thick or wide cross sections.

MasterSil 972TC-LO has a moderate viscosity of 30,000-40,000 cps with good flow

properties and has a one to one mix ratio by weight. It has a long working life

of 6-10 hours at room temperature. This compound is 100% solids and has a white

color. Mastersil 972TC-LO is available in 50 gram syringe kits with additional

sizes upon request.

View website