The Holistic Enhanced Laser Process (HELP) supports you with a perfect marking quality, a maximum process reliability, more production efficiency and less scrap.

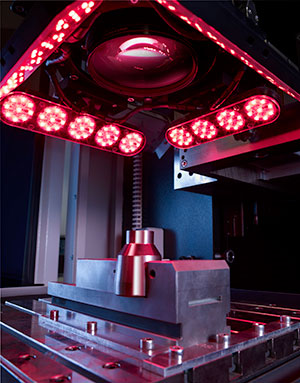

The Holistic Enhanced Laser Process (HELP) supports you with a perfect marking quality, a >maximum process reliability, more production efficiency and less scrap. The foundation for those features is a closed loop process with three stages, realized by an integrated vision system and a customized software.

During the first stage the part gets validated to avoid marking of wrong or defective parts. HELP recognizes the part and aligns the mark relative to the position. It also confirms that only unmarked parts are being processed. The second stage is applying the correct mark directly on the part at the correct position.

The third stage involves the post-mark verification. Has the mark been placed at the right spot? How is the contrast? Is every character and every code readable? Does it match the expected content?

With HELP you can reduce your scrap cost up to 80% and lower your handling and set up time significantly!

Product Benefits:

- Automatic mark alignment, laser-aided processing and verification

- Full traceability and compliance with regulations

- More efficient and flexible production: validation of laser marking directly after marking still inside the machine reduces handling time

- Reproducible, stable process

- Consistent premium-quality markings

- Eliminates possible marking errors and reduces non-conforming parts