Nearshoring Strategy Supports Increased Customer Demand While Upholding Stringent Quality Standards

FREDERICA, DEL., - Sept. 20, 2023 - Flexan LLC, a custom contract manufacturer of medical grade silicone and thermoplastic components, and ILC Dover, a leading provider of innovative single-use solutions for biopharmaceutical and pharmaceutical processing, announced that they have successfully attained ISO 13485:2016 certification for a 15,000 sq. ft. Class 7 cleanroom facility located in Juarez, Mexico. This milestone marks a significant advancement in delivering high-quality, nearshoring solutions to medical device and pharmaceutical customers.

With increasing supply chain challenges and labor-intensive manufacturing requirements, medical device and pharmaceutical companies are increasingly turning to a nearshoring strategy for device assembly, kit packing, and custom component manufacturing, as it offers shorter transportation distance, reduced risk, and easier oversight of the production process.

“This milestone underscores our mutual commitment to deliver top-tier nearshoring solutions to our valued medical device and pharmaceutical customers. With this achievement, we are well-equipped to set new standards in the industry, by offering increased manufacturing capacity and upholding stringent quality control at our Juarez site,” said Corey Walker, CEO of ILC Dover.

The strategically-located site in Juarez now offers several key benefits to Flexan and ILC Dover customers:

Stringent Quality Control

The ISO 13485:2016 certification, issued by the International Organization for Standardization, validates rigorous standards and protocols required within a state-of-the-art designed Class 7 cleanroom, including a strictly-controlled environment that meets meticulous, exacting requirements for cleanliness and air quality in a controlled environment.

Increased Manufacturing Capacity

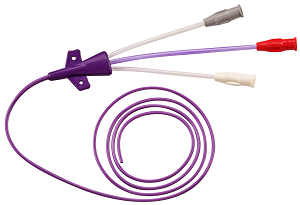

The cleanroom offers expanded kitting and assembly capabilities, which allows the companies to quickly scale production of silicone and thermoplastic medical device components and packaging, allowing for increased demand and reduced lead time.

Strategic Nearshoring Location

The Juarez facility is advantageously located near the U.S. market, which helps mitigate common supply chain issues like transcontinental shipping delays and costs, and a trend among many customers looking to near-shore operations. The Juarez market also has a high density of global medical device and life science company operations, which provides access to a skilled labor force.

In 2021, ILC Dover acquired Flexan to serve a broader range of medical device and biopharmaceutical customers. Together, the companies offer custom design, manufacturing, and assembly of silicone, thermoplastic, and rubber medical device components.

About Flexan

Flexan is a global leader in custom medical device manufacturing, with over seven decades of unparalleled expertise in molding, extrusion, assembly, and packaging solutions. Committed to excellence and innovation, Flexan offers medical device companies the precision, quality, and regulatory compliance necessary to succeed in a competitive market. Its tailored services, which are deeply rooted in silicone, rubber, and thermoplastic polymers, benefit healthcare technology firms worldwide by ensuring the development and delivery of top-tier, compliant products that meet the highest industry standards. For more information about Flexan, visit www.flexan.com.

About ILC Dover

ILC Dover is a world-leader in the innovative design and production of solutions for biopharmaceutical, pharmaceutical, medical device markets as well as a leading supplier for the (aero)space industries. Our customers will attest to our relentless dedication to high value products, advanced technology, and responsive service, as our visionary solutions have improved efficiency while safeguarding people, product, and infrastructure in hazardous conditions through flexible protective solutions since 1947. For more information on ILC Dover, please visit www.ilcdover.com.

Flexan Media Contact:

Margo Pelak 224-543-0003

[email protected]

View website