Bristol Instruments adds production-ready features to its Opti-Cal Software

VICTOR, NEW YORK October 19, 2020 – Bristol Instruments has added a variety of production-ready features to its Opti-Cal Software, included with its family of Optical Thickness Gauges. These systems provide the most accurate and reliable non-contact thickness measurement available. And now, they can further improve the efficiency of manufacturing processes.

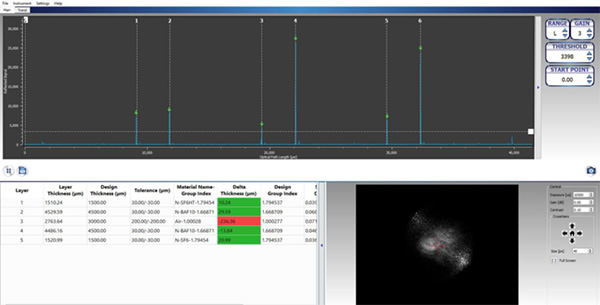

One of the new capabilities of the Opti-Cal software is a QC (Quality Control) mode of operation. This feature automatically compares measured results to the values of a stored design file, and reports whether the part under test is within specified tolerances. This can be done for up to 31 layers. What’s more, the Opti-Cal software provides new tools that make it more convenient to convert the instrument’s optical measurement to the desired physical thickness. This includes a built-in group index lookup table for common optical materials and an integrated calculator to determine the group index of unidentified materials.

“Originally designed for laboratory and R&D environments, Bristol’s Optical Thickness Gauges have evolved into high volume production and in-line quality control tools,” said Don Jarvie, Business Development Manager for Metrology Products at Bristol Instruments. “The improvements in the Opti-Cal software give our users built-in production ready capability on day one.”

About Bristol Instruments

Since its founding in 2005, Bristol Instruments has solely focused on designing, manufacturing, and marketing precision instruments using its expertise in optical interferometry. Bristol’s flagship products accurately characterize the wavelength and spectral properties of lasers and are used by scientists and engineers at universities and government and industrial laboratories. They are also used for the development and production testing of laser transmitters used in optical fiber communications. In addition, Bristol Instruments provides interferometer-based products to reliably measure critical physical dimensions of materials such as specialty plastic films, medical tubing, and ophthalmic products.